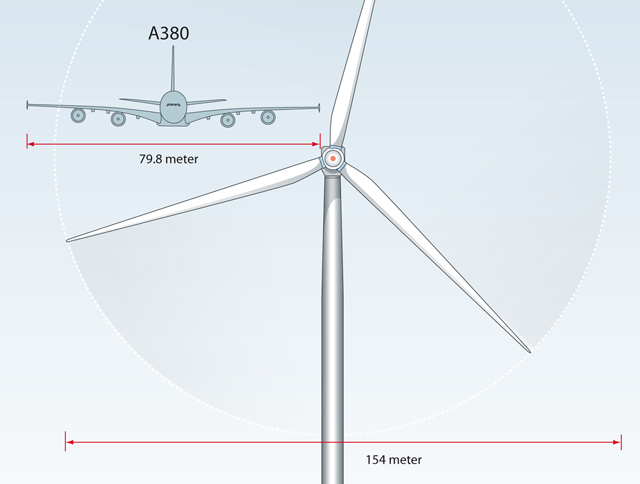

German manufactuer Siemens have constructed off-shore wind turbines with record-breaking rotors. These enormous rotor blades are 75 meters long, which makes a single blade almost as big as the wingspan of an Airbus A380. All in all, the gigantic rotor measures 154 meters and covers about two and a half football fields.

Despite its size the rotor blade weighs 20% less than more conventionally produced blades. This is made possible because of Simenes patented technologies which uses special lightweight materials in its construction process. As you can see from the photo below the entire blade is made as a single piece of "glass fiber-reinforced epoxy resin and balsa wood". Besides making it lightweight, in relation to its size of course, these construction processes also makes the wind turbine extremely strong. And this is a good thing considering that they will be hit with the energy of around 200 tons of air per second out in the sea where these wind turbines are designed to be used. According to Siemens the tips of the 75 meter long blades will be able to move at up to 80 meters per second, or 290 km per hour.

The B75 blade is the world's largest fiberglass component cast in one piece.

So why are manufactures like Siemens trying to build bigger and bigger wind turbines? Well it’s simple really. As the turbine blades get longer the amount of electricity they produce increases very rapidly. And because offshore wind projects are quite expensive it makes sense to build a fewer big wind turbines than lots of small ones.

A prototype 6-megawatt turbine will be erected at the Østerild test station in Denmark later this fall. And in a few years time, 300 of these huge wind turbines will be installed by the Danish energy supplier Dong just off the British coast.

Recommended Comments

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.